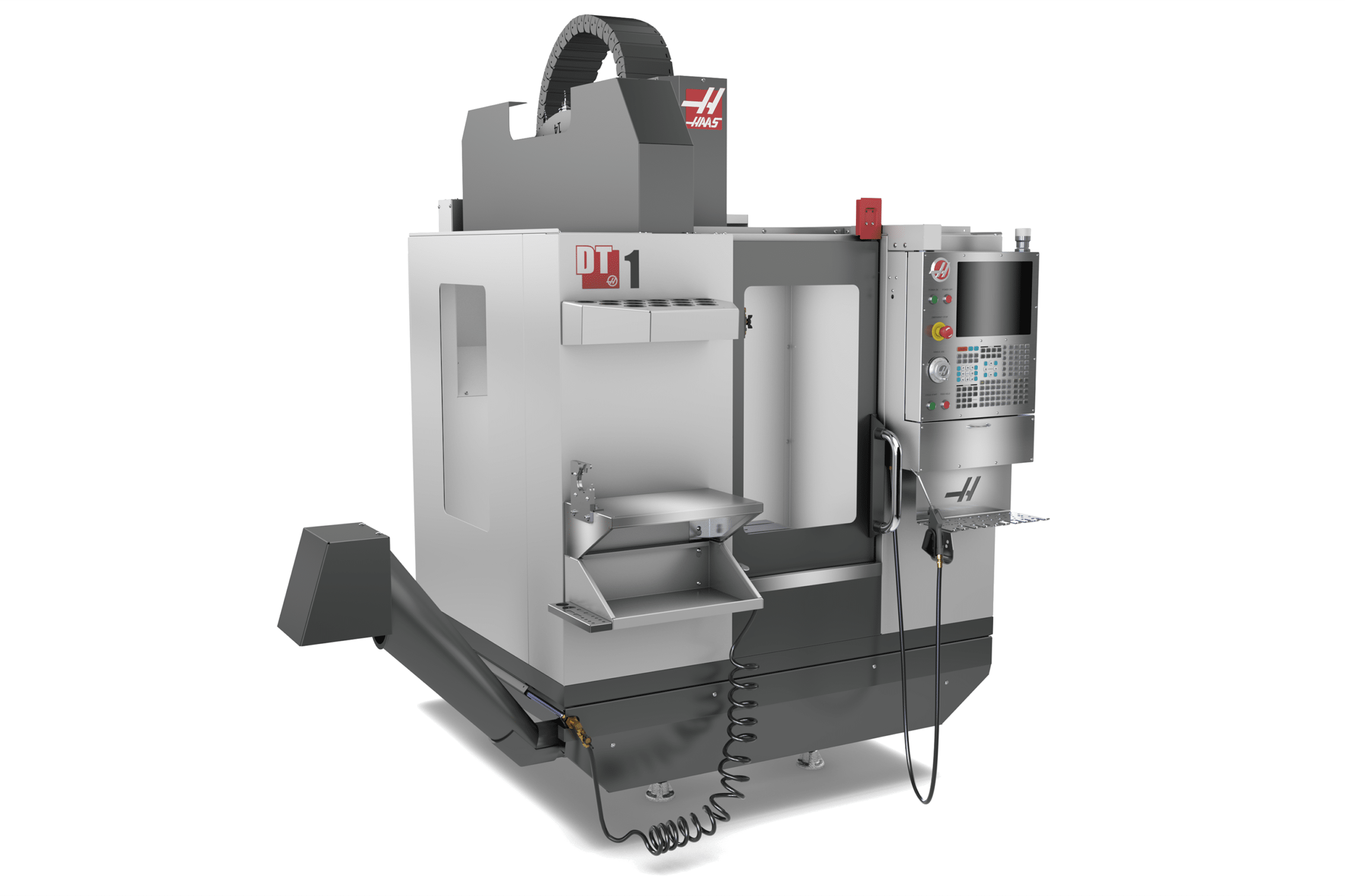

Making Parts with Our New DM-1

We are excited about the addition of our high-speed Precision Haas DM-1 CNC Drill/Mill Center. We want to share with you how we recently used this machine on a project for our client, EP Purification.

EP Purification is on the cutting edge for water purification and disinfection. Instead of using chlorine to treat the water, they use microplasma ozone technology. This is a much healthier and safer alternative to chemical treatment. We at ShapeMaster are excited to be a part of this innovative technology to supply safe and clean water to the world!

Recently, our friends at EP Purification asked us to mill a plain block of polycarbonate into a unique and detailed component. To transform this block, it takes 14 different mills and bits, or as we call it, “Tool Changes”. This means the machine needs to put one bit down and pick another up. When we ran this project on our Haas TM-2, the time in tool changes alone would have been 7 minutes per block. Our high-speed DM-1 on the other hand can handle those same tool changes for the same block in a matter of 45 seconds.

Before we could actually do any work to the polycarbonate block, we had to make aluminum fixtures to hold the block in the DM-1 for milling. We used the DM-1 to create those fixtures. We always look for ways to cut time when making a product. Originally, the final step for this block was to have a person take the almost finished block in their hand, use a special tool and chamfer, or take the sharp edge off, 8 of the 12 sides of the block. Not only was this a time-consuming process, but we could not guarantee that each block would have a uniform edge each time. The DM-1 not only cuts the time for this process from a couple of minutes down to a few seconds, but the DM-1 also produces a uniform, consistent edge every time!

A detailed component such as this requires extreme precision and speed and this is what our Haas DM-1 provides. Since moving the project to our DM-1, we have saved an immense amount of time.