OUR PORTFOLIO

ShapeMaster got its start as a prototype shop designing and manufacturing small and medium sized parts in various gauges of plastic for designers, engineers, entrepreneurs and inventors. Featured here are various projects that required extensive research, “outside the box” creativity, product development, and reaching beyond our limitations to deliver products that meet the needs of our customers.

We encourage you to bring your conceptual ideas to ShapeMaster where we will work with you every step of the way to ensure complete satisfaction and deliver what you once thought to be the impossible.

TerraSentia Robot

Industry: Agriculture

Client Name: EarthSense

Services Provided: Design, Development, and Vacuum Forming

Case Introduction: The customer required a tough two-piece body for a vehicle designed to drive through a cornfield remotely using GPS for guidance. This vehicle would be used to photograph the corn crops, scan for insect infestation and disease and give a report on the health of the crops.

ShapeMaster’s Solution: Our solution was to mold in heavy gauge plastic a top and bottom shell to create a vehicle body that would be easily mass-produced and meet all of the strength requirements.

Box Truck for Animal Transportation

Industry: Agriculture

Client Name: University of Illinois

Service Provided: Custom Design

Case Introduction: ShapeMaster was presented with a unique project: convert an old U-Haul box truck into a vehicle that can transport farm animals to and from appointments.

ShapeMaster’s Solution: We adapted the back of the box truck into a chamber for hauling pigs. The floor was a 1” thick rubber mat we purchased locally that was sold for horse stalls. Next, we built stalls that would collapse when not in use so that the truck could also be used for hauling a variety of materials like bales of hay or other feed products. We also designed a multi-ton lift for raising animals once they are ready in a sling and a hydraulic table gurney for transporting animals to and from a lab where they were to be CAT scanned. Finally, we installed fans and a duct system for adequate airflow for breathing and to keep the environment cool during the hot summers. This has been used for many purposes and has been very helpful for the animal research department at the university.

Police Radar Gun Holster

Industry: Law Enforcement

Client Name: Pulse Technology

Service Provided: Vacuum Forming

Case Introduction: Our client came to us in need of a recreation of a police radar gun holder that was no longer produced that could be used in law enforcement vehicles of all types including cars, boats, and motorcycles.

ShapeMaster’s Solution: We were able to make castings from an existing part, enlarge using sheet wax which compensates for the shrink of the plastic when forming and then make a production tool (mold). From this tool, we vacuum-formed over 100 units and then began trimming on our CNC precision router. This allowed for perfect replication of what the customer needed and once assembled was a beautiful product complete with a strap to hold the radar gun in the holster until retrieved.

N-95 Masks

Industry: PPE

Client Name: University of Illinois

Service Provided: CNC Machining

Case Introduction: During the early stages of the COVID-19 global pandemic, hospitals and healthcare providers across the nation had shortages of N95 Masks and face shields. There was a pressing need for PPE and Jeremy Guest, director of the Environmental Engineering and Science Laboratories in the Department of Civil and Environmental Engineering at the University of Illinois at Urbana-Champaign, set out to help meet the need in the local community by creating a plastic vacuum-formed N95 mask.

ShapeMaster’s Solution: Working with a team of “Makers” from our community, we provided programming, CNC machining of the tooling and molding of the plastic masks along with necessary components that we sourced through a local shop on campus and helped bring this project to fruition.

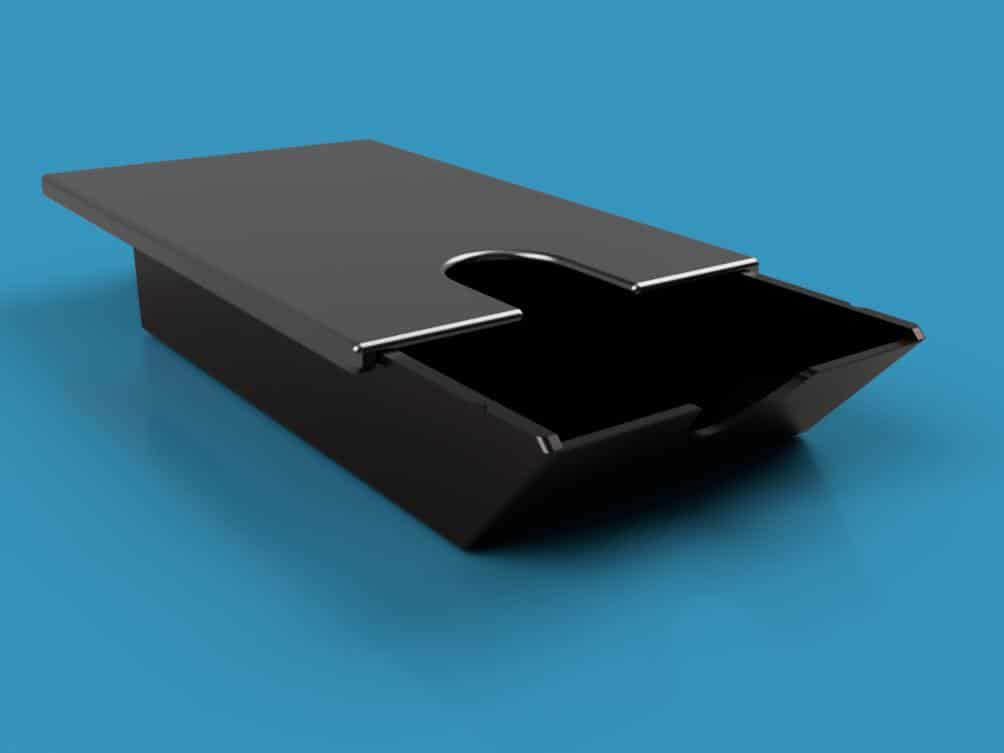

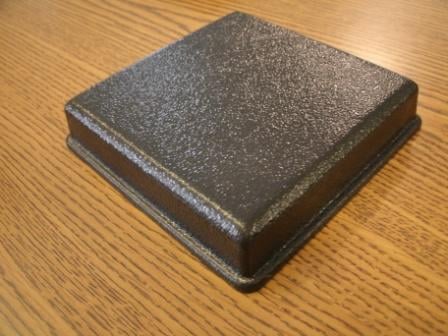

Fingerprint Tray

Industry: Criminal Justice

Services Provided: Injection Molding and CNC Machining

Case Introduction: We recently completed a project for an Illinois State Police retiree who presented us with a common problem in crime scene investigation, the storing of fingerprint cards. His proposition was to create a fingerprint tray to hold fingerprint cards and keep them clean while offering easy dispensing using gloved hands.

ShapeMaster’s Solution: After being presented with this problem, we went to work to turn this tray into a reality. Our in-house engineers have created the injection molding tooling using our CAD/CAM software and our CNC mills. We have just completed injection molding thousands of these trays for the client.

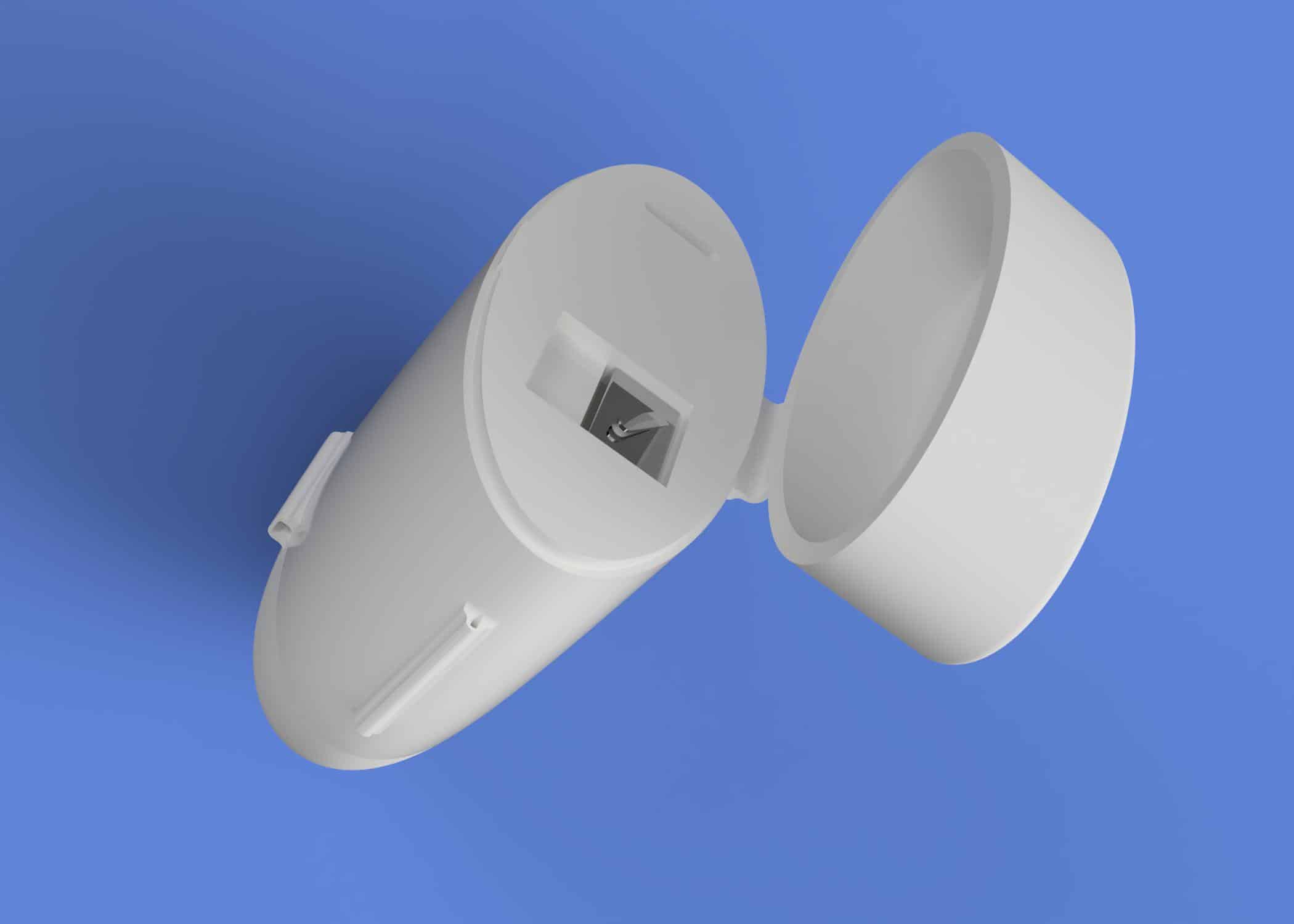

The Floss Boss

Industry: Dentistry

Client Name: Amanda Lewis DMD

Services Provided: Rapid Prototyping and Injection Molding

Case Introduction: Our client presented ShapeMaster with a unique problem to be solved: creating custom packaging that had the capability to dispense both dental floss and a special recipe lip balm.

ShapeMaster’s Solution: Through the use of rapid prototyping and injection molding, we were able to provide the client with a new and improved design for this product. The design allowed for the dental floss to be pulled from the bottom and cut with a cutter that could be covered by the lid when snapped shut. In addition to appearance, this new design offered much more functionality including the ability to utilize pre-wound spools of floss that the client could easily source. The design also offered efficient assembly with parts that easily snap together.

3D Printed Messerschmitt Component

Industry: Aerospace

Client: Midwest Aero Restorations

Service Provided: 3D Printing

Case Introduction: A local Aerospace restoration company was restoring a Messerschmitt Bf 109 and asked us to help them recreate a part from the motor so that it could be recast.

ShapeMaster’s Solution: The client loaned us the part so we could 3D digitally non-contact scan and 3D print it. We then measured the plastic printed part to prove that our scanning and CAD work was accurate. Next, we had to do some repair work to the metal component due to the corrosion it was subjected to in the lake where the German army had sent the airplane. We provided both the CAD files and the 3D printed part to our customer. We can now use that same 3D printed work to send off to an investment casting company and have these parts cast in the same metals as they would have been done in the 1930s when the airplane was made.

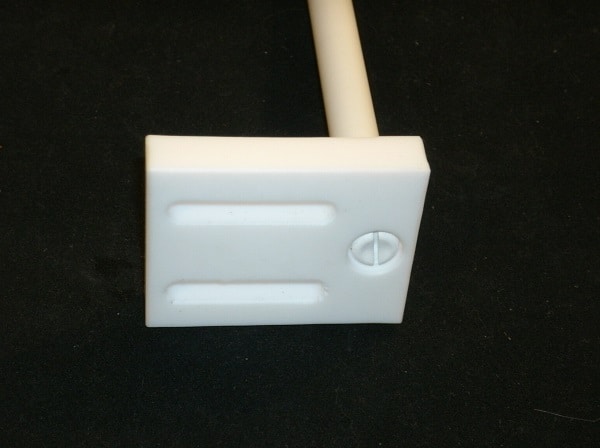

Silicon Wafer Dipper

Industry: Semiconductor

Client Name: Epiworks

Service Provided: CNC Machining

Case Introduction: Originally, a client came to us requiring a custom teflon dipper that could be used to lower a silicon wafer into a vat of acid to etch the pattern onto the disc.

ShapeMaster’s Solution: We were able to listen to the needs of the customer to design, develop, and create CAD models and prints for the wafer dippers. Once the models were accepted by the client, they became a basis for producing a CNC machined finished product. From this initial request, we developed many custom and production units for sale.

Chemical Dispenser for Sanitation Cleaning

Industry: Sanitation

Client: Envirox

Service Provided: Custom Design

Case Introduction: We were presented with a challenge to design and develop a working case for bags of concentrated cleaning chemicals to be diluted for various strengths and dispensed into bottles or mop buckets.

ShapeMaster’s Solution: We first designed the plastic case using sketches, then CAD models. Once approved, we designed a tool in aluminum that would be used for making thousands of dispensers. The finished product allowed for the chemicals to dispense into a water dilution and create a mixed ratio dispensing into buckets for mopping or spray bottles for cleaning.

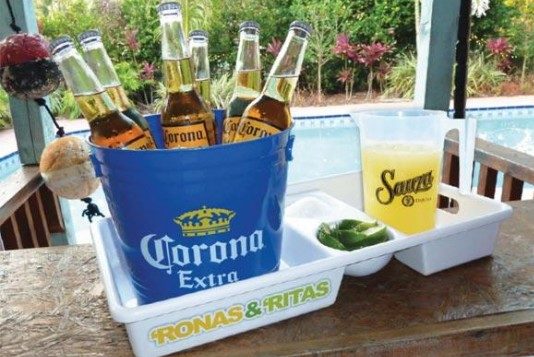

Ronas and Ritas Tray

Industry: Marketing

Client Name: Reisigl Associates, Inc.

Service Provided: Vacuum Forming

Case Introduction: The client, a marketing firm based in Florida, initially came to us with a wooden slat tray. They were asked to create a tray that would hold a plastic bucket of Corona bottles, a plastic pitcher of margaritas, a shallow flat round area for salt that would be used to line your rim with salt, and a molded-in bowl to hold limes.

ShapeMaster’s Solution: We decided that this product would be accomplished best by using vacuum forming. We chose vacuum forming because we can build prototype tooling and mold plastic sheets to test from a product concept. Then once proven, we can have a production tool built which allows us to run a very affordably made tray. We did a few initial runs in glossy white before the customer decided that they wanted to add color to the design. We were able to find a plastic that could be extruded in two colors, one per side.

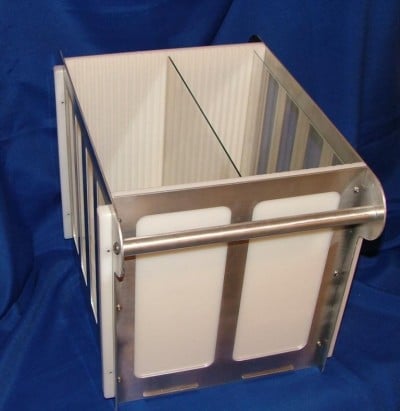

Cassette Holder

Industry: Industrial Lighting

Client Name: Eden Park

Service Provided: Water Jet Cutting and CNC Machining

Case Introduction: The client needed a hybrid metal and plastic basket that would be used to hold panels of glass and lower these into a chamber for coatings. The project needed design, CAD models, prints to figure out the best materials and methods to construct.

ShapeMaster’s Solution: The solution was to create a metal basket that would hold panels of glass for a special process the customer would perform on the panels to create a new lighting/illumination process.

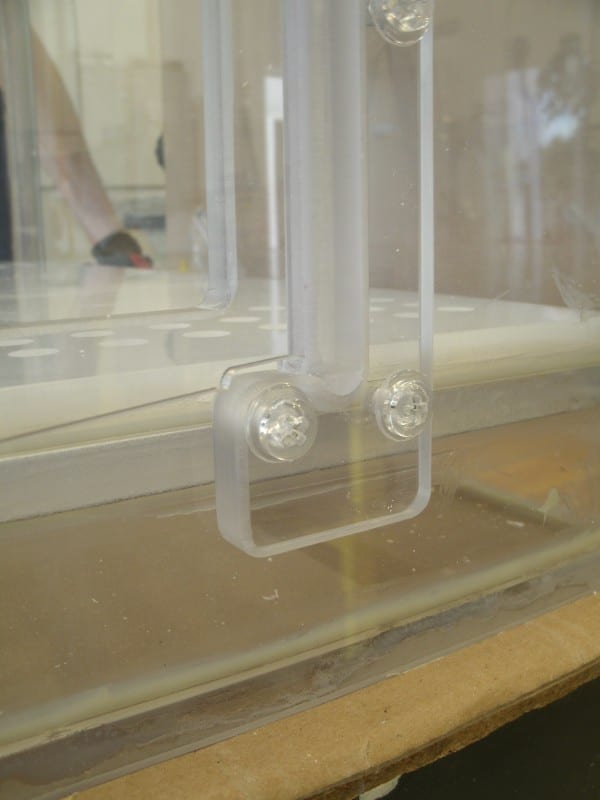

Piglet Cage

Industry: Agriculture Research

Client: Local University

Service Provided: CNC Machining

Case Introduction: The researchers needed to have accessibility to the piglets and be able to easily view them for nutritional cognitive learning research. It was also requested that the enclosures have the ability to comfortably house 6 piglets.

ShapeMaster’s Solution: For this project, we began by using our CAD software to make any necessary changes. We sourced the aluminum fabricated components from one of our vendors. Next, Our Mastercam CNC programs are used to CNC machine route the clear polycarbonate doors. The drain pans were produced with our vacuum/thermoforming process forming abs plastic over a mold we built in-house using our CNC mills.

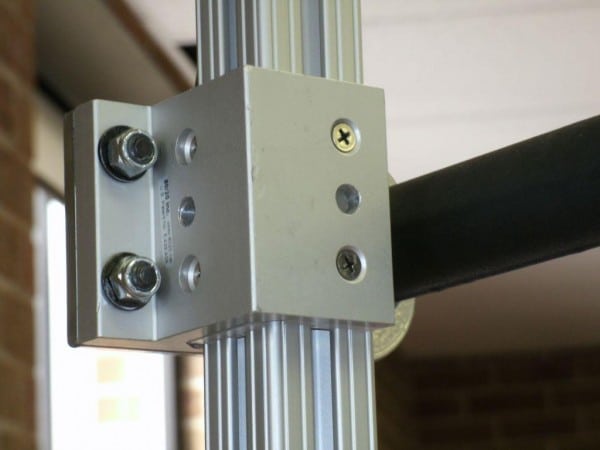

The Posture Rack

Industry: Healthcare

Client Name: Ultimate ChiroCare

Service Provided: Custom Fabrication

Case Introduction: Our client, a local chiropractor, came to us with the idea of developing The Posture Rack. The Posture Rack is a mechanism that allows patients to strengthen their upper body and core.

ShapeMaster’s Solution: We provided a solution to the client using our 8020 T slotted extrusion framework that would mount to a high G force shake table and vibrate the frame and attachments in such a way to create this energy into the bone and muscles of the human body.

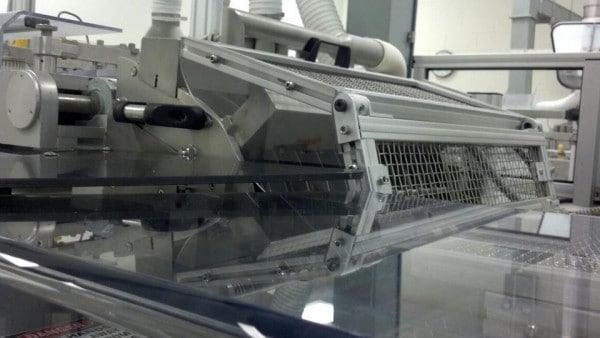

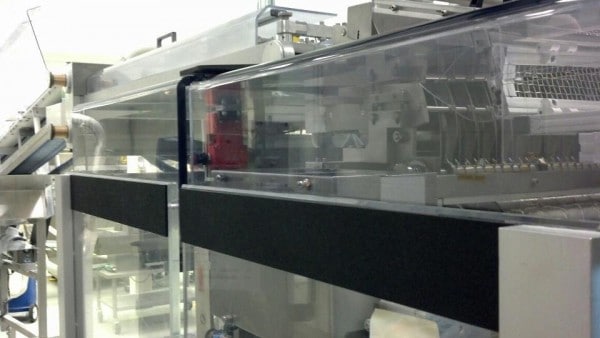

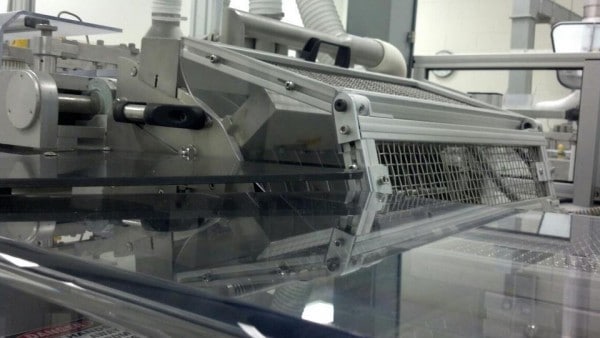

Guarding Install

Industry: Pharmaceutical

Service Provided: Guarding

Case Introduction: This pharmaceutical company was in need of extensive protection for their employees on their assembly lines.

ShapeMaster’s Solution: We installed new Zero Access Guarding on the complete assembly line. This was performed on four separate manufacturing lines.

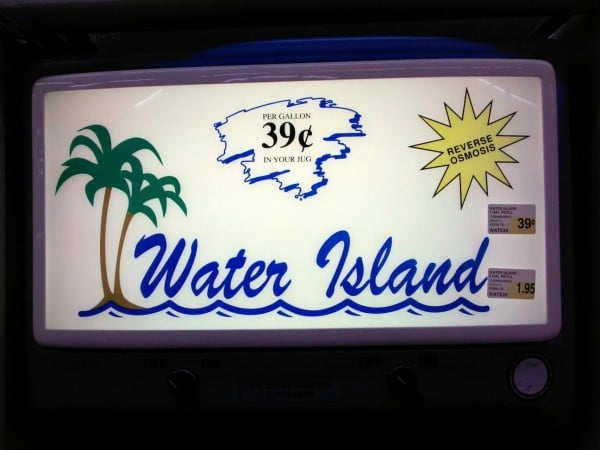

Reverse Osmosis Water Dispenser

Industry: Reverse Osmosis Drinking Water

Client Name: Water Island

Service Provided: Plastic Vacuum Forming and Custom Fabrication

Case Introduction: In conjunction with President and CEO, Dean Robinson, we developed six prototype reverse osmosis water dispenser units. The challenge: Design units that would perform three of the five steps of the reverse osmosis process while allowing the dispensing of water into two one-gallon jugs or one five-gallon and a one-gallon jug simultaneously.

ShapeMaster’s Solution: We accomplished the challenge and did so by taking up less than a 4-sq. ft. footprint of space in a grocery store. In addition to the housing, over 40 component parts were produced by ShapeMaster. We then assembled each system which served as a supply unit to the produce case, baker proofers, drinking fountains, ice machines, and other locations throughout the grocery store. The cabinet is made entirely of ABS thermoplastic molded over a one-piece tool.

House Meter Trays

Industry: Smart Grid Component Manufacturer

Client Name: Landis and Gyr

Service Provided: We were presented with a tray design that a manufacturer of household and industrial meters required in their process and handling. They shared the needs and parameters and we fulfilled their needs by designing and completing a new tray design, tooling, and production. We can now make additional trays easily as they need more in the future.

ShapeMaster’s Solution: Our solution for vacuum form trays is always to consider the need, design for the environment and demand, address the quantity required, quote the project which will involve CAD modeling prints that are dimensioned, and once approved create the tooling from which we will make the final product in production. Once tooling and fixtures are created we will then keep these in our warehouse inventoried and insured for future production of the same item.

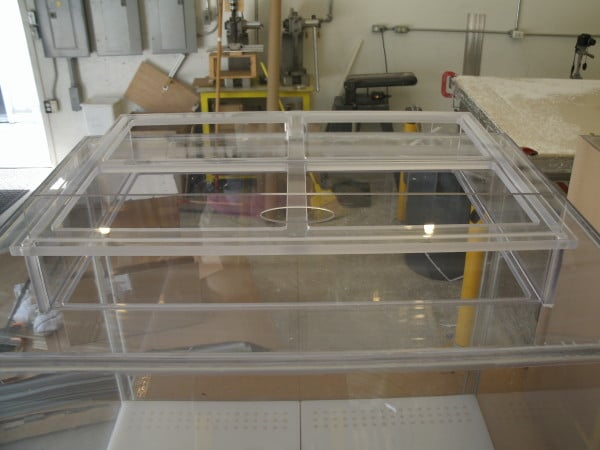

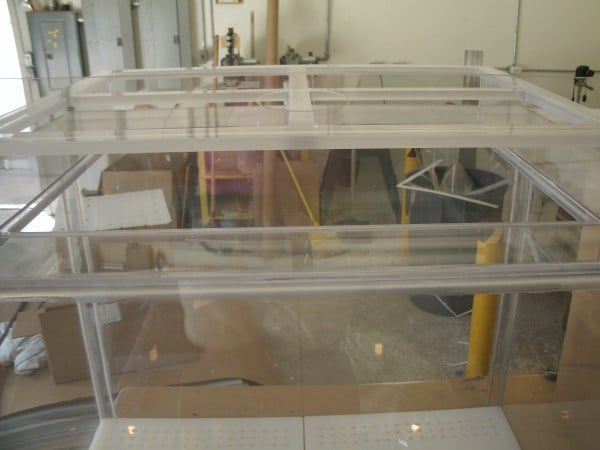

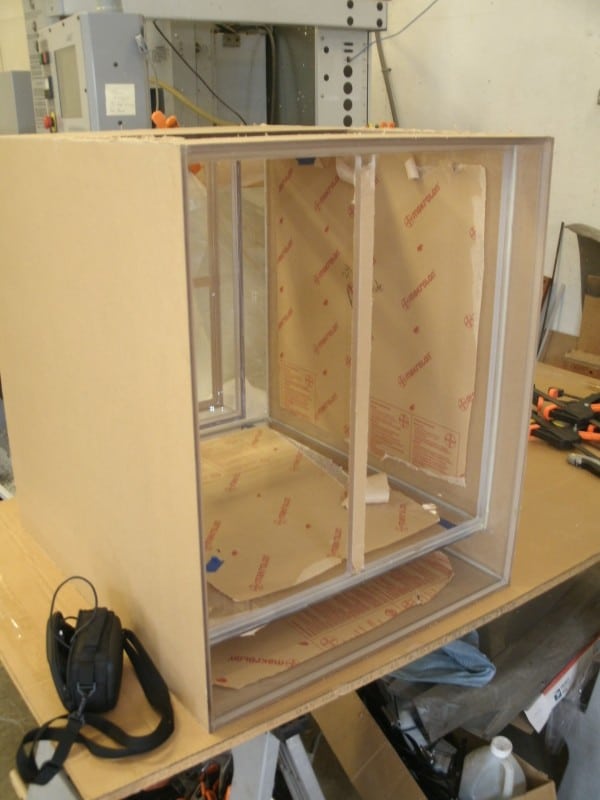

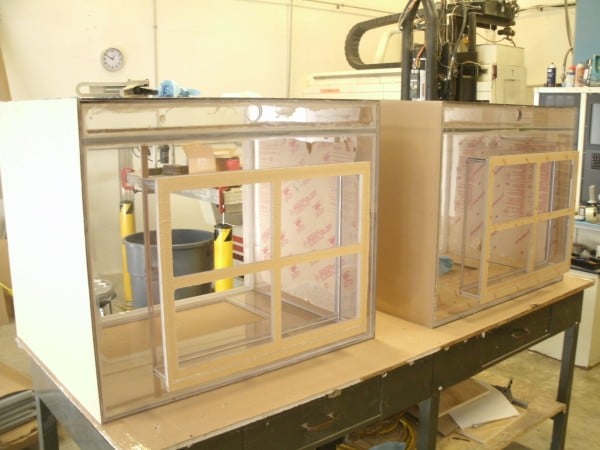

Fabricated Polycarbonate Boxes

Industry: University Research

Client: University of Missouri

Case Introduction: Researchers at the University of Missouri were in need of polycarbonate boxes that they could utilize for research.

ShapeMaster’s Solution: We were able to provide boxes with the bottom made of polypropylene and the rest of the box made of polycarbonate.

Soft Drink Signs for Sporting Events

Industry: Advertising

Service Provided: Custom Design

Case Introduction: We were asked to produce a sign that could be lit up using LED lighting inside the case and held by a person while walking around sporting events to draw attention to them and the fact they were selling cold soda pop of various brands.

ShapeMaster’s Solution: We used the dimensions they gave us and specified the plastic sheet for this project that would offer a white translucency for glowing brightly at night. Once the graphics were installed on the sign the unit would look like a Coca-Cola or Pepsi round disc sign face.

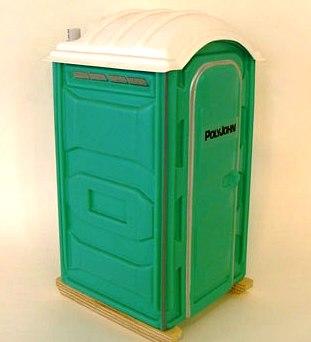

Porta Potty Banks

Industry: Portable Toilets

Client: Polyjohn

Case Introduction: The client is a portable toilets company that was in need of a miniature version of their Polyjohn PJ3 that could be used as a piggy bank to give away for promotions.

ShapeMaster’s Solution: We were able to utilize vacuum forming to provide the customer with a miniature piggy bank version of their Polyjohn PJ3 that looked identical to the full-size version.

CNC Fabricated Basketball Men

Industry: Sports

Client: Basketball Trainer

Case Introduction: A local coach was in need of a way to turn his idea of custom fabricated basketball men into a reality with the goal of using them to help players become better shooters.

ShapeMaster’s Solution: Through the use of CNC plastic routing, we used a combination of pipe and machined special rings and bosses to mount pipe to stock injection molded bases.

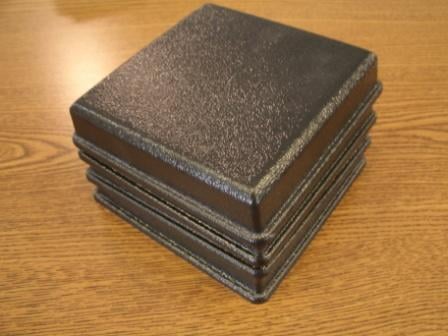

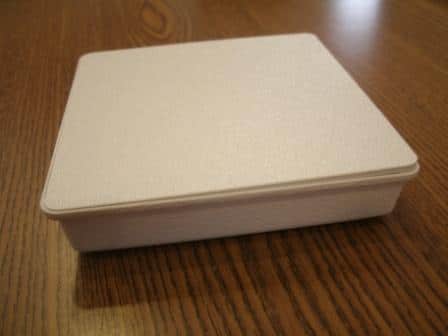

Custom Electronic Enclosures

Industry: Electronics

Service Provided: Vacuum Forming

Case Introduction: The client came to us in need of a handheld case or enclosure for circuit boards for electronics projects that varied from joystick controls for agriculture machines to a custom shut-off device for ice fishing cabins used on a propane heater to prevent carbon monoxide poisoning.

ShapeMaster’s Solution: We designed a box using simple tooling and then vacuum-formed thousands of these to meet customer demand.

Hang ‘Em Awl

Industry: Hardware

Client Name: Amr Megahed, M.D. Pediatrics

Service Provided: Injection Molding and Metal Turning

Case Introduction: The client was in need of a simple way to hang pictures of different mounting styles.

ShapeMaster’s Solution: We created a mass-producible product that aided in hanging pictures by designing this product in plastic with metal components, sourcing the parts custom made, and injection molding the plastic ourselves. We then assembled and packaged the finished product for retail sales.

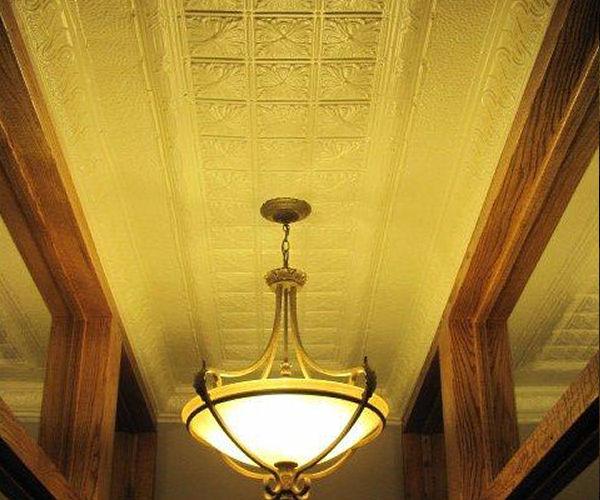

Tin Ceiling Renovation Project

Industry: Renovation

Client: Insurance Office in Historic Building

Case Introduction: An insurance company purchased a building to restore for their new office. When the drop ceiling was removed they found the original tin tile ceiling; however, a number of tiles had been destroyed or removed during a prior remodel.

ShapeMaster’s Solution: Our solution was to make plaster molds to replicate the metal tins and set them up for vacuum forming. We molded white polystyrene high impact paintable plastic for the tiles which could be easily trimmed by laborers in the reconstruction process to ensure an exact fit.

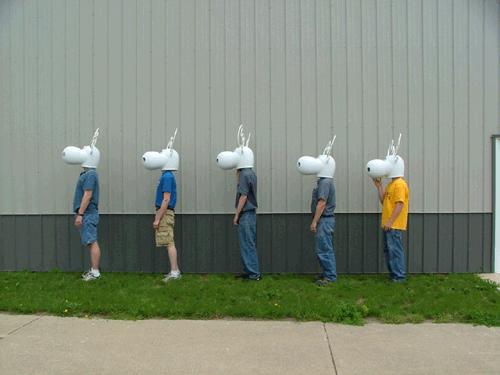

Moose Head Mascot

Industry: Costume

Client: Thomas Creative Apparel

Case Introduction: Our client makes full-sized costume apparel for unique applications. They were presented with making a Tommy the Moose costume that adults would wear when walking in parades to promote a banking firm in Ohio.

ShapeMaster’s Solution: We were given photos and a logo and from this created a full-sized moose head that fit over a human head and allowed for a Mascot of Tommy the Moose to be in parades. We made approximately 100 of these during our years of working on this project.

Tomato Stem Icon

Client: Pizza Restaurant

A flying tomato serves as the icon (or logo) for a local pizza restaurant. The challenge: Construct a tomato stem out of molded plastic (vs. former models of fiberglass) for use on top of their red pizza delivery vehicles. The fiberglass stems they had used in the past faded and they preferred something more realistic as the fiberglass versions had customers asking if the icon was a chicken foot! Due to the size of the delivery vehicles, the tomato stem and leaf assembly needed to be over 40-inches in diameter. At that time, our equipment was not capable of forming something so large. Thus, we opted to form six individual leaves to first create the leaf assembly and then created the stem by forming two halves and bonding them together. The leaves were bolted together and the stem was bolted to a bracket attached to the leaves. Since the leaf assembly was bolted together, we were able to modify it later when our client decided to adapt the tomato stems to be used as patio umbrella toppers.

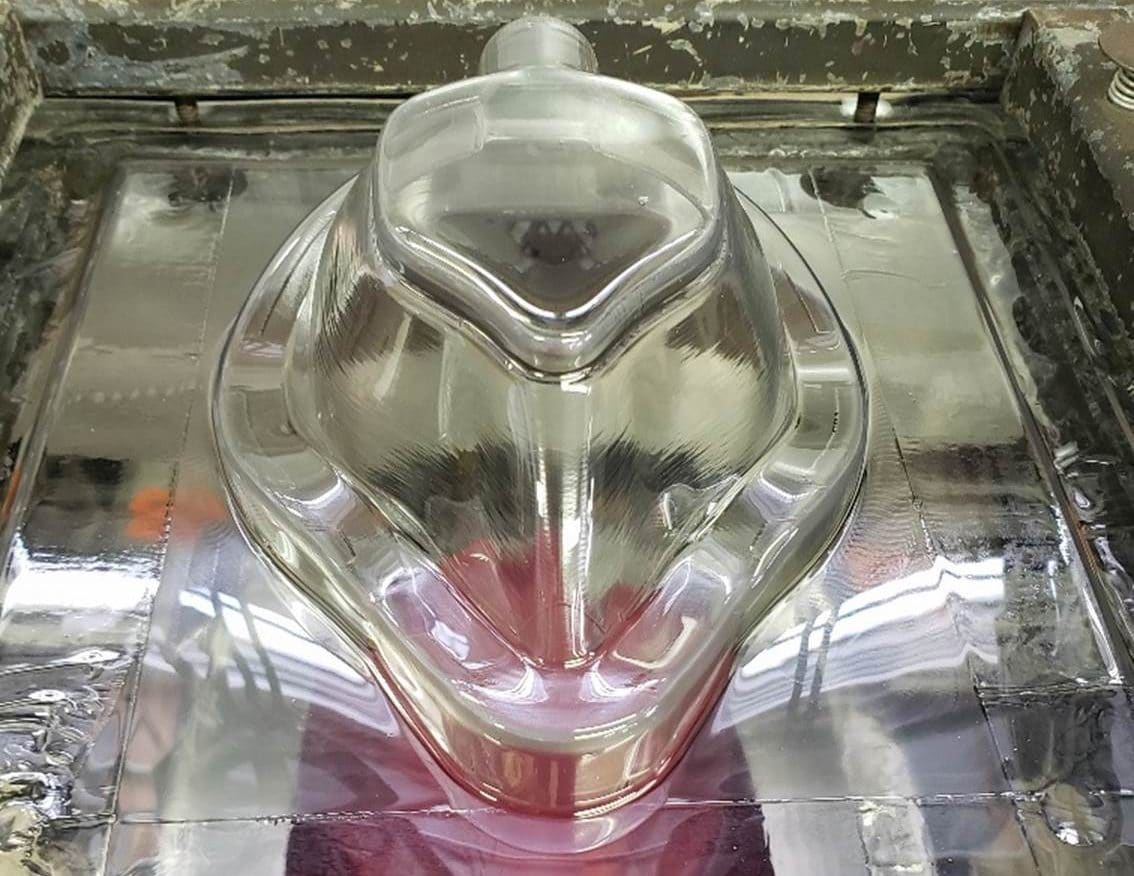

Custom Motorcycle Accessories

Client: Suzuki M50

We are passionate about Suzuki M50 motorcycles and thus began designing and manufacturing parts for M50 bikes. Our custom chin spoiler was created to replace the stock Suzuki radiator cover. Following the curved design of the M50, our custom chin spoiler results in that sleek look you have always wanted, creating a little “attitude” on the front of your bike. Manufactured of ABS molded plastic, our chin spoiler features either a silver mesh or honeycomb grille finish and comes painted in flat black, gloss black, or wet sanded and ready for the paint color of your choice. Add flames, decals, or bolt on neat metal items to make your own statement. The air flow is great and you’ll experience no problems with overheating. Simply bolt on the black powder coated custom metal bracket we include and in less than 15 minutes your bike looks hotter than your neighbors and cooler than any other M50 on the road, until they too buy a ShapeMaster custom chin spoiler! Product tests have been performed at speeds up to 105 mph on rough roads, including crazy peg dragging. You won’t find a better designed product!

Crows for a Fundraising Project

Industry: Entertainment

Client: Danville, Illinois Theater

Services Provided: Injection Molding and Metal Turning

Case Introduction: The Danville, Illinois area has a problem with crows and they wanted to incorporate the much-hated crow for the town to rally help for the theater and to have a parade.

ShapeMaster’s Solution: We were able to assist the customers with their desire to make a stand-up Crow in plastic that would be mounted to a concrete block and used for promotion of an event to raise money to help save the Theater in Danville, IL.

Custom Podium

Client: The Vineyard Church Urbana

ShapeMaster recently designed and engineered a new product out of 8020 for a local church.

Problem: Old podium with one height for various pastors. Existing systems had been music stands, and an older wooden lectern; however this did not have a logo on the front nor an opportunity to height adjust.

Solution: Using 80/20, we created a professional and innovative product that adjusts for the height of different pastors while displaying the logo of The Vineyard Church. This new unit was created from 8020, aluminum panels, machined plastic, and custom powder coating.